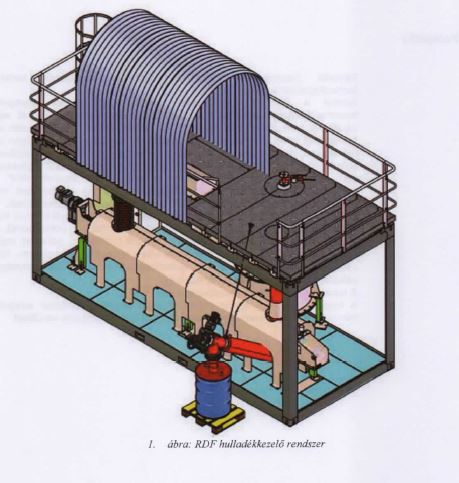

K+F project had been awarded to EBH INVEST: development of a thermodegradation waste processing reactor

The technology and the prototype to be developed by EB HUNGARY INVEST Kft. and Vitruvius Construction Ltd. is a flexible -for

consumer scaling-, continuous and cost-effective waste recycling process. According to the environmental standards we would like to transform the waste into valuable raw materials without using any added catalysts. Our main target is to research and develop thermodegradation processes primarily related to the processing and utilization of mixed municipal waste (RDF).

During the technological development, we are researching the characteristics and accessibility of RDF and other raw materials.

We work on an admixture process that could be fitted to the thermodegradtion process, produce quasi-homogeneous blend stocks that can model the correctness of our system and investigate RDF’s thermodegradation processing technology. Based on our sophisticated theoretical and practical approaches to the technology and the results of our research we develop an equipment based on the degradation by heat that is capable of absorbing and utilizing RDF waste at an industrial scale. As a third step of our development, we will further develop thermodegradation technology to meet industry and market needs, by developing the thermodegradation processing technology for RDF and RDF blends and other raw materials. The readiness of the prepared novelty and the prototype are going to be the same as the industrial model’s, which will be rated by a third-party, independent laboratory and certifying body, so that both the technology and the prototype would be industrial-protected, marketable products (TRL 8-9 ). The product that is being developed by our researchers includes the following novelty elements: An externally heated thermal degradation reactor for the continuous processing of solid raw materials, which transfers the heat to the reactants by the equally spaced infrared heating units around the surface of the contiguous reaction vessel.

We work on an admixture process that could be fitted to the thermodegradtion process, produce quasi-homogeneous blend stocks that can model the correctness of our system and investigate RDF’s thermodegradation processing technology. Based on our sophisticated theoretical and practical approaches to the technology and the results of our research we develop an equipment based on the degradation by heat that is capable of absorbing and utilizing RDF waste at an industrial scale. As a third step of our development, we will further develop thermodegradation technology to meet industry and market needs, by developing the thermodegradation processing technology for RDF and RDF blends and other raw materials. The readiness of the prepared novelty and the prototype are going to be the same as the industrial model’s, which will be rated by a third-party, independent laboratory and certifying body, so that both the technology and the prototype would be industrial-protected, marketable products (TRL 8-9 ). The product that is being developed by our researchers includes the following novelty elements: An externally heated thermal degradation reactor for the continuous processing of solid raw materials, which transfers the heat to the reactants by the equally spaced infrared heating units around the surface of the contiguous reaction vessel.

The radiators are integrated in at least two or three rows on both sides of the reactor’s wall and their combustion products are drawn inside the reactor house. The heating power of the heating units can be controlled individually or in groups. The rotation speed of the reaction vessel can be varied, and the spiral rotation on the inner wall of the container will allow to adjust the time required for the reactions in a wide range. We are going to control the raw material stream, the rotation speed of the vessel and the heating capacity of the heating units by continuous process so that the raw material will stay in the vessel cc. 30-60 minutes while the working temperature will be around 450-500°C. According to our plans a container full of pressurized inert gas will be connected to the raw material feed-system. The reducing medium will be superheated water vapor or carbon dioxide. The competitive advantage of the equipment and the technology, as well as the continuous work of our developers will ensure the sustainability of project results. We are convinced that based on the theoretical foundations, our research results that have been done so far and our finished board model, EB HUNGARY INVEST Ltd. and Vitruvius Ltd. will be able to develop an excellent technology and identify customer value creation. Future potential of the product is the current readiness of the project as well as continuous market demand assessment. From the formation of the theoretical foundations, we investigate waste market actors both from buyers and sellers alike, both at home and abroad too. As a result of that, over the years we have gained insights into the internal market providing us various knowledge of the behaviour of relevant market players, competitors, regulatory bodies and authorities, and the decision-making positions of successful and unsuccessful waste utilization technology developments.